EPS sandwich wall panel machine for sale

Basic Info

Model No.: FP18

Product Description

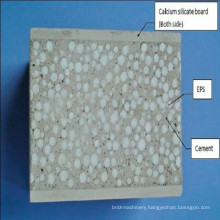

Part 2: Introduction of finished wall panel 2.1 Performance of finished wall panel 1. Simple & firm installation. 2. Frim joint structure of male and female channels. 3. Simple box imbedding, pipe and pipeline installation. 4. Better anti-impact capacity. 5. Easy cutting and processing, Better Waterproofing 6. More anti-bending breaking load. 7. Low thermal conductivity. 8. Sound-insulation, Fireproofing,Heat-inslution, Friednly-environment. 2.2 Advantages of finished wall panel 1, Molding machine is specially designed and made to produce sandwich wall panel. 2, Reliabale mechanics performance: mechanics performance of the compound wallboards is all in the head of the wallboard include it's impact resist, perch up strength, press, transverse resist. 3, The door frame board can or buried in advance directly because of improving the intensity of core bode, fix window frames of different types directly. 4, the product has sound insulation, fireproofing, and environmental protection. 2.3 Raw material for producing wall panel

Part 2: Introduction of finished wall panel 2.1 Performance of finished wall panel 1. Simple & firm installation. 2. Frim joint structure of male and female channels. 3. Simple box imbedding, pipe and pipeline installation. 4. Better anti-impact capacity. 5. Easy cutting and processing, Better Waterproofing 6. More anti-bending breaking load. 7. Low thermal conductivity. 8. Sound-insulation, Fireproofing,Heat-inslution, Friednly-environment. 2.2 Advantages of finished wall panel 1, Molding machine is specially designed and made to produce sandwich wall panel. 2, Reliabale mechanics performance: mechanics performance of the compound wallboards is all in the head of the wallboard include it's impact resist, perch up strength, press, transverse resist. 3, The door frame board can or buried in advance directly because of improving the intensity of core bode, fix window frames of different types directly. 4, the product has sound insulation, fireproofing, and environmental protection. 2.3 Raw material for producing wall panel  2.4 Sample of finished wall panel

2.4 Sample of finished wall panel

Type | JQ1000 With lift port | JQ1000 |

Charging Volume(L) | 1600 | 1600 |

Discharging Volume(L) | 1000 | 1000 |

Max. Grain Size of Aggregate(mm) | 5 | 5 |

Speed of Mixing Blade(r/min) | 26.4 | 21.9 |

Mixing Blade(PCS) | 6 | 6 |

Model of Mixing Motor | XWD8-59-15kw | |

Power of Mixing Motor(KW) | 15 | 15 |

Model of Winch | 500.3 | ---- |

Power of Winch(KW) | 4.5kw/i=20.27 | ---- |

Height of Unloading Material(mm) | 1850 | 1850 |

Model of Water Pump Motor | 3 phase self-sucking pump | |

Power of Water Pump Motor | 1.1KW | 1.1KW |

Frame Dimension in Working | 3900×4728×4382 | 3900×1550×5750 |

Frame Dimension | 7560x6060x6565 | 7560x3065x6565 |

Net Weight(T) | 6.2 | 5.5 |

Function | Molding system | |

Finished Wall Panel Dimension | 3000x600x75/90/100/150/200mm | |

Output of Wall Panel with Different Thickness | 75mm | 14 PCS |

90mm | 12 PCS | |

100mm | 11 PCS | |

150mm | 8 PCS | |

200mm | 7 PCS | |

Hydraulic Unit | Motor power | 2.2 KW |

Operating Pressure | 3-4Mpa | |

Molding Time | Two Hours (High aluminium cement) | |

Net Weight | 5 T | |

Component | Host machine, hydraulic station, mould | |

Part 5: Application of wall panel

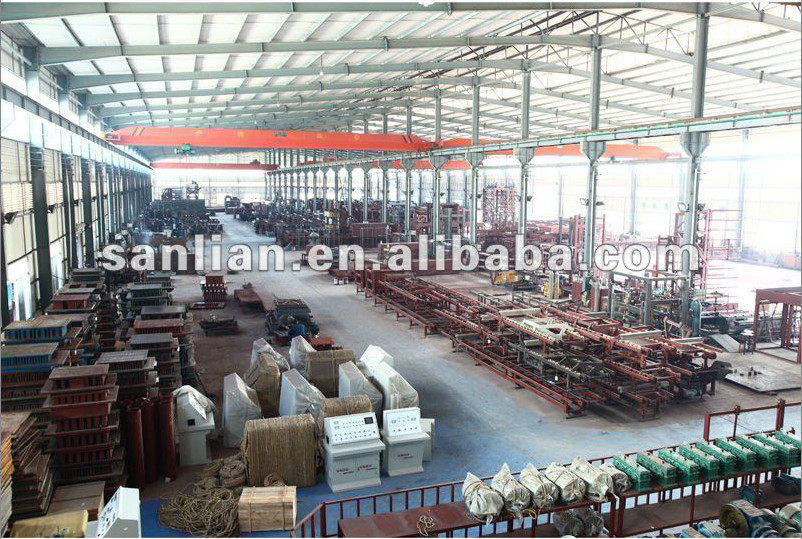

Part 5: Application of wall panel  Company information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in wall panel making machine. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world such as Europe, America, Africa, Middle East, South East Asia, based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced technology, first-class standard, strict management, perfect service system. Our company has 140,000m2 of modern industrial park and 50,000m2 of standard workshop. Our office & workshop

Company information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in wall panel making machine. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world such as Europe, America, Africa, Middle East, South East Asia, based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced technology, first-class standard, strict management, perfect service system. Our company has 140,000m2 of modern industrial park and 50,000m2 of standard workshop. Our office & workshop

Our company fully implement ISO9001 Quality Management System, 14001 Environment Management System, and OHSAS18001 System, and our products have been granted CE Certificate. We are awarded many certificates such as “Star enterprise”, “Contract keeping and Credit First Company”, “High technology Enterprise”,etc in China. Our customers around the world

Our company fully implement ISO9001 Quality Management System, 14001 Environment Management System, and OHSAS18001 System, and our products have been granted CE Certificate. We are awarded many certificates such as “Star enterprise”, “Contract keeping and Credit First Company”, “High technology Enterprise”,etc in China. Our customers around the world  Our services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers. FAQ Q1: What does your factory produce? A: We mainly make Block Machine for producing various kinds of block, as well as wall panel machine and Concrete Mixing Plant. Q2: Where are your facotry? A: Our factory is located at Binjiang Mechanical Equipment Industrial Base,Xiamei Town,Nan’an Quanzhou City,Fujian Province,China. Q3: What about your standard delivery date? A: Usually the delivery time is 30-45days.For some simple case, we can make it shorter time. Q4: How will you treat quality complaint? A: First of all, all of our goods are strictly tested and inspected before delivery, which reduces the possibility of quality problem to near zero. If this is really a quality problem caused by us, we will definitely fix the problem, send you free goods for replacement or refund your loss. Q5: How do your after-sale service work if the product get damaged? Q: In the guarantee time 12 months, our general after-sale service freely provide replacements for damaged parts for our customers, but if the damaged could be repaired by slight cost,we would wait for the customers bill for the fix cost and refund this part of cost (note: Vulnerable parts are not included). Contact Information

Our services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers. FAQ Q1: What does your factory produce? A: We mainly make Block Machine for producing various kinds of block, as well as wall panel machine and Concrete Mixing Plant. Q2: Where are your facotry? A: Our factory is located at Binjiang Mechanical Equipment Industrial Base,Xiamei Town,Nan’an Quanzhou City,Fujian Province,China. Q3: What about your standard delivery date? A: Usually the delivery time is 30-45days.For some simple case, we can make it shorter time. Q4: How will you treat quality complaint? A: First of all, all of our goods are strictly tested and inspected before delivery, which reduces the possibility of quality problem to near zero. If this is really a quality problem caused by us, we will definitely fix the problem, send you free goods for replacement or refund your loss. Q5: How do your after-sale service work if the product get damaged? Q: In the guarantee time 12 months, our general after-sale service freely provide replacements for damaged parts for our customers, but if the damaged could be repaired by slight cost,we would wait for the customers bill for the fix cost and refund this part of cost (note: Vulnerable parts are not included). Contact InformationMost welcome your consluting

It's our honor to help you understand more about our machine. Contact us if you need more details on Wall Panel Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about EPS Sandwich Wall Panel Machine、Wall Panel Machine for Sale. If these products fail to match your need, please contact us and we would like to provide relevant information.

It's our honor to help you understand more about our machine. Contact us if you need more details on Wall Panel Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about EPS Sandwich Wall Panel Machine、Wall Panel Machine for Sale. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Wall Panel Production Line

Premium Related Products