precast foam cement wall panel\lightweight wall panel machine\eps concrete sandwich wall panel

Basic Info

Model No.: Statinary Molding Machine

Product Description

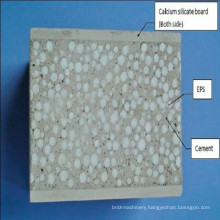

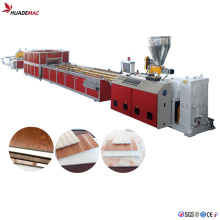

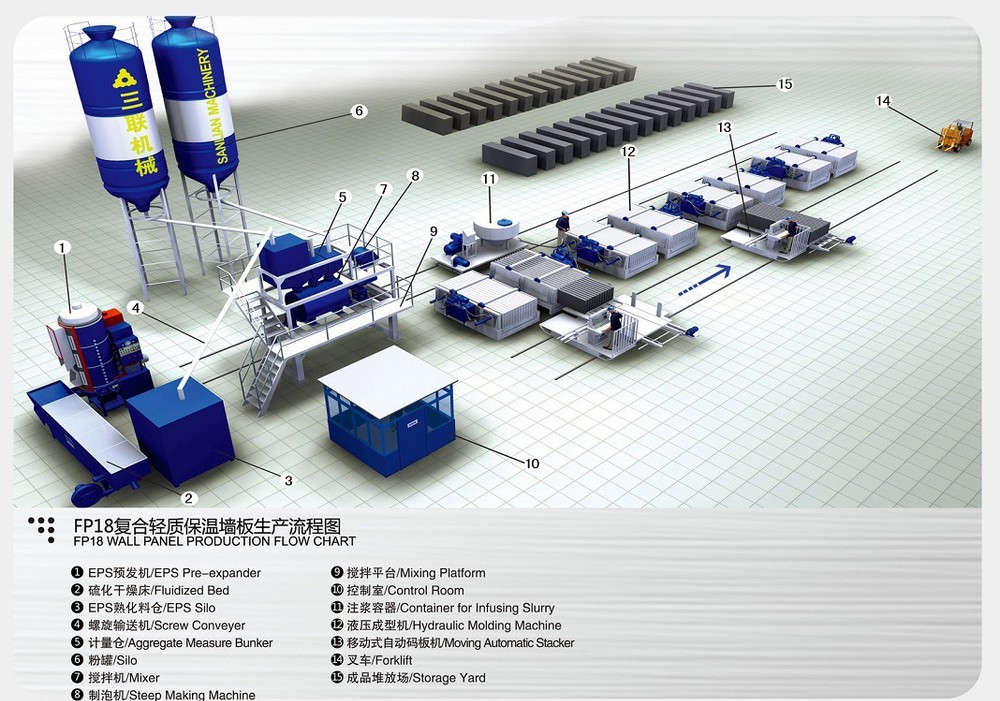

1.Introduction of wall machine production line (Compound) heat preserving Lightweight Wall Panel adopts the newly high technology from South Korea, which is produced with the policy of lower investment but higher profit. 2.It includes five systems: Batching System, Mixing System, Slurry-infusing System, Molding System, and Automatic Demoulding System. 3.Process of producing: Material batching → mixing → slurry infusing → molding →automatic demoulding and stacking→ finished product 4. Raw material: cement, eps foam, fly-ash, sand, ceramiste, cement board, calcium silicate board, and some chemical additives Technical Parameter of Mixer

1.Introduction of wall machine production line (Compound) heat preserving Lightweight Wall Panel adopts the newly high technology from South Korea, which is produced with the policy of lower investment but higher profit. 2.It includes five systems: Batching System, Mixing System, Slurry-infusing System, Molding System, and Automatic Demoulding System. 3.Process of producing: Material batching → mixing → slurry infusing → molding →automatic demoulding and stacking→ finished product 4. Raw material: cement, eps foam, fly-ash, sand, ceramiste, cement board, calcium silicate board, and some chemical additives Technical Parameter of Mixer Type | JQ1000 With lift port | JQ1000 |

Charging Volume(L) | 1600 | 1600 |

Discharging Volume(L) | 1000 | 1000 |

Max. Grain Size of Aggregate(mm) | 5 | 5 |

Speed of Mixing Blade(r/min) | 26.4 | 21.9 |

Mixing Blade(PCS) | 6 | 6 |

Model of Mixing Motor | XWD8-59-15kw | |

Power of Mixing Motor(KW) | 15 | 15 |

Model of Winch | 500.3 | ---- |

Power of Winch(KW) | 4.5kw/i=20.27 | ---- |

Height of Unloading Material(mm) | 1850 | 1850 |

Model of Water Pump Motor | 3 phase self-sucking pump | |

Power of Water Pump Mo | 1.1KW | 1.1KW |

Frame Dimension in Working | 3900×4728×4382 | 3900×1550×5750 |

Frame Dimension | 7560x6060x6565 | 7560x3065x6565 |

Net Weight(T) | 6.2 | 5.5 |

Function | Transferring the material and inject material into wall panel molding machine under high pressure |

Infusing Volume | 1m³ |

Working Pressure | 0.4Mpa |

Motor Power | Traveling motor: 1.1KW Aircompressor motor: 3KW |

Frame Dimension | 2755x1200x1665mm |

Component | Slurry container, rail, air compressor, pipe |

Function | Molding system | |

Finished Wall Panel Dimension | 3000x600x75/90/100/150/200mm | |

Output of Wall Panel with Different Thickness | 75mm | 14 PCS |

90mm | 12 PCS | |

100mm | 11 PCS | |

150mm | 8 PCS | |

200mm | 7 PCS | |

Hydraulic Unit | Motor power | 2.2 KW |

Operating Pressure | 3-4Mpa | |

Molding Time | Two Hours (High aluminium cement) | |

Net Weight | 5 T | |

Component | Host machine, hydraulic station, mould | |

Function | (Pulling panel out off wall panel molding machine,collecting wall panel together ,turning over wall panel with 90°,and taking wall panels to the outside with forklift ) | ||

Motor Power | Hydraulic Unit Motor | 6.6kw |

|

Traveling Motor | 1.5kw |

| |

Demoulding Motor | 1.1kw |

| |

Cylinder Travel | Wall panel pushing cylinder | 1200mm |

|

Turnover Cylinder | 650mm |

| |

Weight | 2.2T |

| |

Component | Hydraulic unit motor, Turnover Machine, Demoulding Device, Wall panel pushing device , rail ,traveling motor,Electrical control cabine |

| |

Frame | 4350×3612×1150mm |

| |

Our Services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers.

Our Services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers.

Company Information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD.. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in Concrete Block, heat insulation block, color pavement brick machinery, grass planting brick machinery, slop-protection brick machinery, Curbstone Machinery etc. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced techniques, first-class standard, strict management, perfect service system.

Company Information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD.. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in Concrete Block, heat insulation block, color pavement brick machinery, grass planting brick machinery, slop-protection brick machinery, Curbstone Machinery etc. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced techniques, first-class standard, strict management, perfect service system.

Project Photo Customers Case of Wall Panel Machine

Contact us if you need more details on Eps Concrete Sandwich Wall Panel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lightweight Wall Panel Machine、Precast Foam Cement Wall Panel. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Eps Concrete Sandwich Wall Panel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lightweight Wall Panel Machine、Precast Foam Cement Wall Panel. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Wall Panel Making Machines

Premium Related Products