Prefabricated House Eps Cement Sandwich Wall Panel Production Line\Eps Wall Sandwich Panel Machine

Basic Info

Model No.: Vertical Molding Machine

Product Description

Product Description 1.Introduction of wall machine production line (Compound) heat preserving Lightweight Wall Panel adopts the newly high technology from South Korea, which is produced with the policy of lower investment but higher profit. 2.It includes five systems: Batching System, Mixing System, Slurry-infusing System, Molding System, and Automatic Demoulding System. 3.Process of producing: Material batching → mixing → slurry infusing → molding →automatic demoulding and stacking→ finished product 4. Raw material: cement, eps foam, fly-ash, sand, ceramiste, cement board, calcium silicate board, and some chemical additives Advantages 1, Molding machine is specially designed and made to produce sandwich wall panel. 2,Reliabale mechanics performance: mechanics performance of the compound wallboards is all in the head of the wallboard include it's impact resist, perch up strength, press, transverse resist. 3, The door frame board can or buried in advance directly because of improving the intensity of core bode, fix window frames of different types directly. 4, the product has sound insulation, fireproofing, and environmental protection. Performance of Wall Panel Simple & Firm Installation Firm Joint Structure of Male and Female Channels Simple Box Imbedding, Pipe and Pipeline Instillation Better Anti-impact Capacity Easy Cutting and Processing, Better Waterproofing More Anti-bending breaking load Low Thermal Conductivity Sound Insulation, Fire Proof, Friendly Environment, Increase in usable Area, Reduce Structure Cost and Save Construction Time

Our Services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers.

Our Services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers.

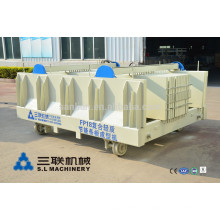

Company Information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD.. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in Concrete Block, heat insulation block, color pavement brick machinery, grass planting brick machinery, slop-protection brick machinery, Curbstone Machinery etc. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced techniques, first-class standard, strict management, perfect service system.

Company Information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD.. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in Concrete Block, heat insulation block, color pavement brick machinery, grass planting brick machinery, slop-protection brick machinery, Curbstone Machinery etc. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced techniques, first-class standard, strict management, perfect service system.

Project Photo Customers Case of Wall Panel Machine

Contact us if you need more details on Prefabricated House Eps Sandwich Wall Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Cement Sandwich Panel Production Line、Eps Wall Sandwich Panel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Prefabricated House Eps Sandwich Wall Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Cement Sandwich Panel Production Line、Eps Wall Sandwich Panel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Function | Molding system |

Feeding Capacity | 5M3 |

Finished wall panel dimension | 2440*600*75000 |

Molding time | 2hours |

Net weight | 5ton |

Component | Host machine, hydraulic unit, mould |

Note: our production line can make different size according to customers’ specific request. | |

Our Services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers.

Our Services 1. Send Professional engineer to the jobsite to supervise the installation and commission of the plant; 2. Related training will be provided to the customer's operators face-to-face; 3. Response to customer's questions in 24-hour; 4. Provide wearing parts and related spare parts; 5. Provide lifetime technical support; 6. Provide technical upgrade for customers.

Company Information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD.. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in Concrete Block, heat insulation block, color pavement brick machinery, grass planting brick machinery, slop-protection brick machinery, Curbstone Machinery etc. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced techniques, first-class standard, strict management, perfect service system.

Company Information QUANZHOU CITY SANLIAN MACHINERY MANUFACTURE CO., LTD.. is located in Binjiang mechanical equipment industrial base, Xiamei Town, Nan’an City, Fujian Province. Sanlian Machinery is a manufacturer specializing in Concrete Block, heat insulation block, color pavement brick machinery, grass planting brick machinery, slop-protection brick machinery, Curbstone Machinery etc. Our company has developed into a High-Tech Enterprise due to our feasible technology R&D, reliable machinery manufacturing, outstanding sales performance and considerate after-sale service. Sanlian machinery are well sold all around the world based on a professional quality constituted by leading technology and excellent workforce, sophisticated equipment, advanced techniques, first-class standard, strict management, perfect service system.

Project Photo Customers Case of Wall Panel Machine

Contact us if you need more details on Prefabricated House Eps Sandwich Wall Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Cement Sandwich Panel Production Line、Eps Wall Sandwich Panel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Prefabricated House Eps Sandwich Wall Panel Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Eps Cement Sandwich Panel Production Line、Eps Wall Sandwich Panel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Wall Panel Making Machines

Premium Related Products

Other Products

Hot Products

LB1500 Hot sale new automatic asphalt mixing plant for sale in ChinaEPS Panel MachineJQ1000 Lightweight Aggregate MixerPrecast Lightweight Wall Panel Production LineConcrete brick making machineAutomatic Brick Machine(concrete block machine,block making machine,hollow block machine)Simple production line(block machine, brick machine, brick making machine)Block splitter, block cuttercement brick making machineFull Automatic Production Line of Block Making Machineblock full automatic production lineLightweight wall panel making machinelightweight wall panel plant projectBatching machine PL1600SLPL600X300 block cutterbrick making machine QFT12-15