Click on the follow link to find out more information: https://www.hdbrickmachine.com/concrete-block-making-machine/

Company Info

- Company Name: Nantong Hengda Non-burned Machinery Engineering Co.,ltd

- Representative: YUANHAO CUI

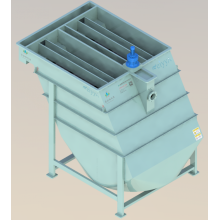

- Product/Service: Brick Machine , Vacuum Extruder , Block Machine , Tunnel Kiln , PVC Pallet , Double Shaft Mixer

- Capital (Million US $): 1,680,000.00RMB

- Year Established: 2007

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 21% - 30%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- OEM Services Provided: yes

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: 180# CHANGJIANG WEST ROAD,HAIAN TOWN,NANTONG CITY,JIANGSU PROVINCE,CHINA

- Contact Person: Mr. Austin Qiu

- Tel: +86-513-88801016

Email to this supplier

Premium Related Products

Other Products

Hot Products

LB1500 Hot sale new automatic asphalt mixing plant for sale in ChinaEPS Panel MachineJQ1000 Lightweight Aggregate MixerPrecast Lightweight Wall Panel Production LineConcrete brick making machineAutomatic Brick Machine(concrete block machine,block making machine,hollow block machine)Simple production line(block machine, brick machine, brick making machine)Block splitter, block cuttercement brick making machineFull Automatic Production Line of Block Making Machineblock full automatic production lineLightweight wall panel making machinelightweight wall panel plant projectBatching machine PL1600SLPL600X300 block cutterbrick making machine QFT12-15